Ngokombono wokwakheka kwezinto ezibonakalayo, ama-carbide roll ama-carbide alungiswa kakhulu yinqubo ye-powder metallurgy nge-powder metallurgy inqubo ngokusebenzisa ama-refluctory metalgy Inqubo (njenge-tungsten carbide wc, njt aungsten carbide wc, njt aungsten carbide wc, njt. Le nhlanganisela ekhethekile yezinto zokwakha inika i-tungsten Carbide igoqa ubulukhuni obuphezulu, gqoka ukumelana nokumelana nokungamelana nokukhathala okushisayo, kubenza bakwazi ukubekezelela ukugqokwa okukhulu, okuvezwa ngejubane eliphezulu. I-ceramic roll isuselwa ezintweni ze-ceramic futhi icutshungulwe yinqubo ekhethekile. Izinto ze-ceramic ngokwazo zinobulukhuni obuphezulu kakhulu kanye nokuphikiswa okuhle kakhulu, okwenza i-ceramic roll yenze kahle kwinqubo yokugoqa, ikakhulukazi esimweni sezidingo eziphakeme zombuso.

Ngokuya kwezimpawu zokusebenza, ama-tungsten Carbide Roll ayaziwa ngokumelana kwawo ukugqokwa kanye nokumelana nokukhathala okushisayo. Inobulukhuni obuphezulu nokuqina okuhle okushisayo, futhi kungagijima isikhathi eside isikhathi eside endaweni yokushisa ephezulu kanye nokulayisha okuphezulu, okuthuthukisa kakhulu ukusebenza kahle kokusebenza kwesigayo sokugoqa. Ngaphezu kwalokho, ama-tungsten Carbide Roll nawo anokuphakelana okuhle okushisayo, okungasusa ngokushesha ukushisa okwenziwe ngesikhathi senqubo yokugoqa, ukunciphisa izinga lokushisa komhlaba, futhi kunciphise ukulimala kwengcindezi eshisayo kuma-rolls. Ngakolunye uhlangothi, ama-rolls we-ceramic, ngakolunye uhlangothi, abonakala ngobulukhuni bawo aphezulu, ukumelana nokugqwala nokuqina okushisa okuphezulu. Izakhiwo ezikhethekile zezinto zokwenziwa kwe-ceramic zenza ama-ceramic rolls akulula ukuba kube lula ukukhiqizwa ngamakhemikhali ngesikhathi senqubo yokugoqa, futhi angagcina ukuqeda nokunemba kwendawo ende ye-roll isikhathi eside. Ngasikhathi sinye, ama-ceramic roll angagcina ukusebenza ezinzile ezindaweni ezishisa kakhulu, futhi ngeke adake noma athambe ngenxa yokunyuka kwamazinga okushisa.

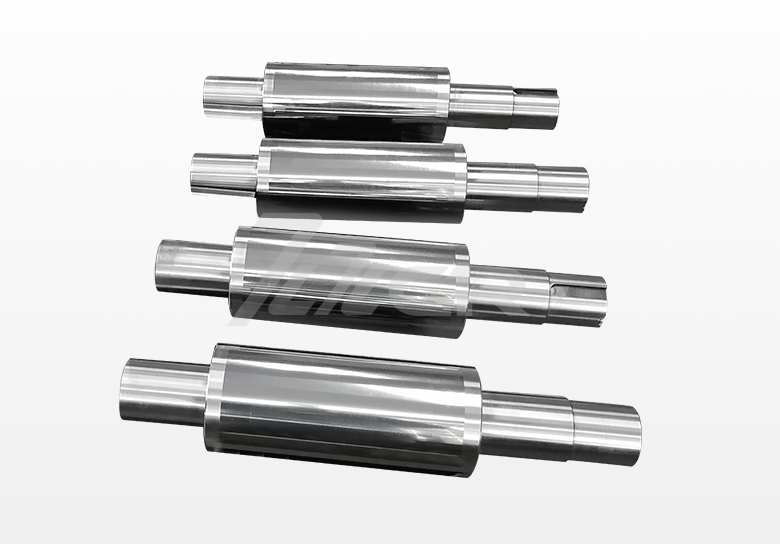

Ngokuya kwesicelo, ama-carbide rolls ahlanganisiwe asetshenziswa kabanzi ekukhiqizweni kwensimbi, izinsimbi ezingezona ezi-forrrous, izinto zokwakha kanye nezinye izimboni ngenxa yezakhiwo zazo ezinhle kakhulu. Ikakhulu emandleni aphezulu, izindawo ezihamba phambili ezihamba kahle njenge-wire-speed wire rod rolling mills futhi uqede ama-rolling mill, ama-carbide rolls adlale indima engenakuphikwa. Ama-rolls we-ceramic asetshenziswa kabanzi emigqeni yokukhiqiza eshisayo nebandayo embonini yensimbi, ukukhiqizwa kwe-ceramic, ukucubungula ingilazi kanye nokuphikisa ngogesi ngenxa yobulukhuni bawo obuphezulu, ukumelana nokushisa okuphezulu.

Isikhathi sePosi: Sep-02-2024