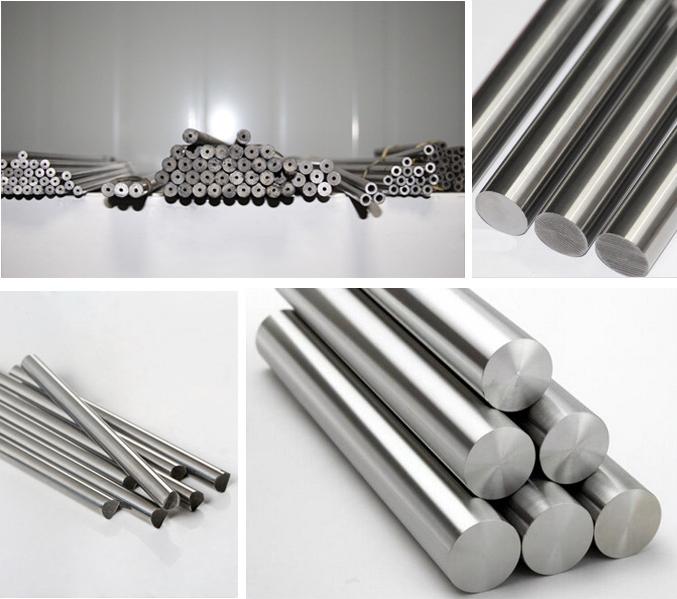

I-Tungsten Carbide Rod yi-tungsten Carbide Round Bar, eyaziwa nangokuthi ibha yensimbi yeTungsten, okulula ukusho, i-tungsten Steel Round Bar noma ibha ye-tungsten Carbide Round Round. I-Tungsten Carbide iyinto ehlanganisiwe ekhiqizwa yi-powder metallurgy futhi yakhiwa amakhompiyutha wensimbi okuvuselelayo (isigaba esinzima) kanye nezinsimbi ezihlanganisiwe (isigaba se-brinder).

Kunezindlela ezimbili ezakhayo zokukhiqizwa kwemigoqo eyindilinga yeTungsten Carbide Caryiel: Okukodwa kokukhishwa, nokukhishwa kuyindlela efanelekile yokukhiqiza imigoqo emide. Ingancishiswa kunoma yibuphi ubude obufiswa ngumsebenzisi ngesikhathi senqubo yokukhishwa. Kodwa-ke, ubude obusezingeni eliphakeme abungeke badlule abangama-350mm. Okunye ukuxhumanisa kokucindezela, okuyindlela efanelekile yokukhiqiza isitoko esifushane. Njengoba igama libonisa, i-carbide powder enesihlahla ehlanganiswe icindezelwa ngesimo ngesikhunta.

I-Carbide efakwe ngesiqeshana inochungechunge lwezinto ezinhle kakhulu ezinjengobulukhuni obuphezulu, gqoka ukumelana, amandla amahle kanye nokuphikisa, okuhlala ubulukhuni bayo obukhulu, futhi kuhlala bulukhuni balo oluphezulu, futhi busebulukhuni obukhulu ngo-1000 ° C. I-Carbide yeTungsten isetshenziswa kabanzi njengezinto zokwakha amathuluzi, njengamathuluzi okuguqula, ama-milling cutter, ama-plastiti, ukunciphisa amatshe kanye nensimbi ephakeme, i-porsic, ukugawula insimbi ephakeme (insimbi yamathuluzi nezinye izinto ezinzima zokugaya (i-ball mill, IKhabhinethi yoMlolo, i-Z-Mixer, i-Granulator ---), icindezela (nge-Side Pressure Hydraulic Cindezela noma i-extuder),

Izinto ezivuthiwe zigaya, ukomisa, i-coug doping, bese ukomisa nokuncishiswa kwengcindezi ngemuva kokubumba noma ukukhishwa, futhi ekugcineni kwakha i-alloy yokugcina ngokukhokhelwa kabusha nokukhonkotha.

Ukungathandeki kokukhiqizwa kokukhishwa kwebhande eliyindilinga ukuthi umjikelezo wokukhiqiza mude. Ukucisha amabha amancane abuyimitha aphansi ngaphansi kwe-3mm futhi ukwephula amaphethelo amabili kuzochitha inani elithile lezinto ezibonakalayo. Ubude obude be-carbide encane ububanzi ibha yokujikeleza, okubi kakhulu kokungenalutho. Vele, ukuqonda kanye nobuhlakani kanye nokuzungeza kungathuthukiswa ngokugaya kwe-cylindrical ngokuhamba kwesikhathi.

Okunye ukukhiqizwa kokucindezelwa, okuyindlela ekhiqizwa ngayo isitoko esifushane. Njengoba igama libonisa, kuwukubumba okucindezela i-carbide ye-carbide ebekwe esimweni. Inzuzo yale ndlela ye-carbide bar yokwenza ukuthi ingakhiwa ngokudlula okukodwa futhi inciphise isikhafu. Yenza lula inqubo yokusika ucingo futhi ususe umjikelezo obonakalayo owomile wendlela yokukhishwa. Isikhathi esifushane esinqunyelwe singagcina amakhasimende izinsuku ezingama-7-10.

Ukukhuluma ngokuqinile, ukucindezela okusobala futhi kungokwemibumba yokucindezela. Ukucindezela oku-Isstatic kuyindlela ekahle ekwakheka ekwakhiweni kwemigwaqo emikhulu ye-tungsten Carbide Round. Ngezimpawu ezingenhla neziphansi zePiston, iphampu yengcindezi ifaka i-liquid medium phakathi kwesilinda esiphakeme kakhulu kanye nerabha elicindezelwe, futhi ingcindezi idluliselwa ngerabha elicindezelwe ukuthi licindezelwe.

Isikhathi Seposi: Jan-24-2024