Ngenxa yobulukhuni obuphezulu obuhlukile kanye nokumelana okuqinile kokugqoka, i-carbide eyenziwe ngesibili isetshenziswa kabanzi embonini futhi yaziwa njengezinyo lezimboni. Kodwa-ke, imikhiqizo ye-carbide eyenziwe ngesihlanu nayo ithambekele ekuboleni nasekuguqukeni ngesikhathi sokucutshungulwa. Namuhla, sizokwazi ukuhlaziya izizathu zokushintshana ngokonakala kwemikhiqizo ye-carbide eyenziwe ngesibili, futhi uthole izindlela ezingavinjelwa ekuguqukeni kwezingxenye.

Umkhiqizo weTungsten Carbide uhlobo lwe-tungsten carbide njengezinto eziphambili eziluhlaza, usebenzisa indlela ye-powder metallurgy ngokugaya kwebhola, ukuqina, ukumelana, ukumelana nokugqwayiza, ukumelana nokugqwala, ama-disc, ama-disc, imigoqo eyindilinga, imichilo noma ibumbe ibe yi-carbide ekhethekile ekhethekile ekhethekile.

Kunezizathu eziningi ezithinta ukuguquguquka nokugoba imikhiqizo ye-carbide eyenziwe ngesibili, futhi kuyadingeka ukuhlaziya isimo esithile semikhiqizo ye-carbide efakwe ngocingo, engabangelwa yinto eyodwa noma inhlanganisela yezici. Izizathu eziphambili yilezi: i-carbon gradient, i-cobalt gradient, izinga lokushisa, i-gradient yemikhiqizo ecindezelwe, ukulayishwa kwesikebhe esingafanele, i-shrinkage coefflic, njll.

Emakhenishini we-lathe, kuvame ukusetshenziselwa amandla e-centripetal ukusebenzisa i-cruck enamahlathi amathathu noma amane emhlathini we-lathe ukubopha izingxenye, bese kusebenza. Ngale ndlela, kulula ukudala ushintsho ekunembeni kwemishini ngaphansi kwesenzo samandla.

Kulula ukuzidela ngemuva kokwelashwa okushisa.

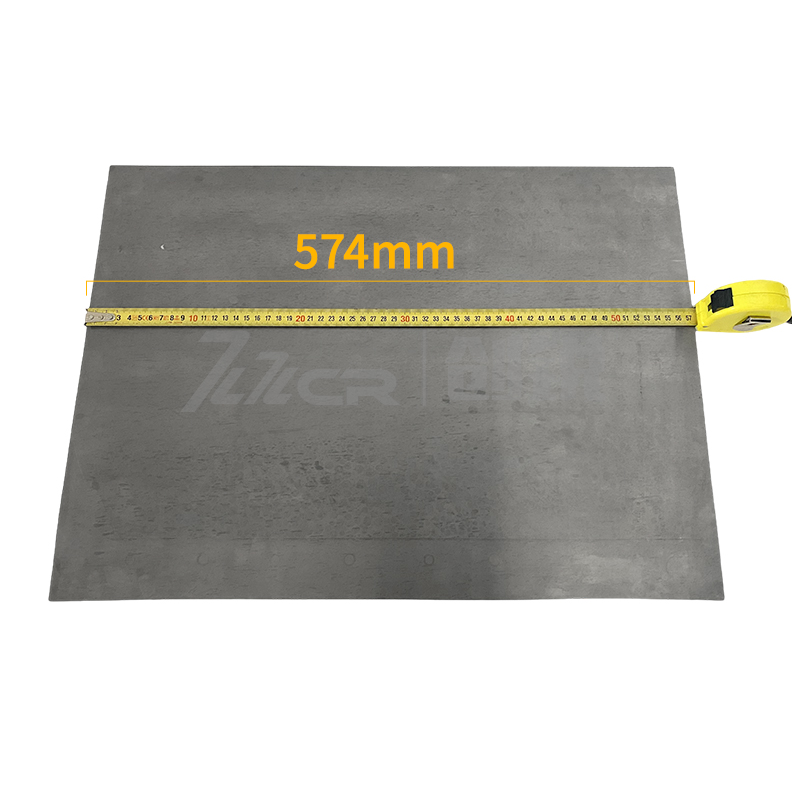

Ngezingxenye ezicijile zeshidi elishiywe, ngenxa yobude babo obukhulu nobubanzi, maningi amathuba okugoba ngemuva kokwelashwa okushisa. Kungahle kube khona into evundizayo phakathi, ukuphambuka kwendiza kuyanda, ngakolunye uhlangothi, ngenxa yethonya lezinto ezahlukahlukene zangaphandle, izingxenye zigobile.

Kukhona nokuwohloka kwe-elastic okubangelwa amandla angaphandle

Lapho wenza umshini we-tungsten Carbide Machining, kunezizathu ezimbalwa eziphambili zokuguqulwa kwezingxenye. Okokuqala, uma ukwakheka kwangaphakathi kwezinye izingxenye kuqukethe amashidi amancanyana, kuzoba nezidingo eziphakeme zendlela yokusebenza, uma kungenjalo lapho opharetha ebeka izingxenye futhi akwazi ukuhambisana nesizukulwane sokudonswa kwe-elastic. Okwesibili ukungalingani kwe-lathe kanye nokuhlanganiswa, ukuze amandla ezinhlangothini zombili zengxenye azilingani, okuholela ohlangothini oluncane ngesikhathi sokusika, futhi ingxenye izolimala ngaphansi kwesenzo samandla. Okwesithathu, ukuma kwezingxenye zenqubo yokucubungula akunangqondo, ukuze ubuzwe namandla ezingxenye ancishisiwe. Okwesine, ukuba khona kwamandla okusika nakho kungenye yezizathu zokulimala kwezingxenye.

Zonke lezi zinto zonke ezibangela ukugoba nokuguqulwa kwemikhiqizo ye-carbide eyenziwe ngesibili. Kufanele sinake kakhulu inqubo yokucubungula, uma nje kwenzeka deformation, khona-ke umsebenzi we-WorkPhintsha ungashaywa kuphela, ungasaphathwa eyokuchitha kabusha imfucuza, ukhiye ukuphinda usebenzise kabusha, ubambezele kabusha ukulethwa kwamakhasimende.

Isikhathi sePosi: Meyi-08-2024