I-Tungsten Carbide Strip yenziwa ikakhulukazi nge-WC Tungsten Carbide ne-Coobalt Powder ehlanganiswe yi-Metallurgical Method ngokusetshenziswa kwe-WC kanye ne-Co, okuqukethwe kwe-WC kanye ne-CO ngokusetshenziswa okuhlukile kweTungsten Carbide strip akufani, futhi uhla lubanzi kakhulu.

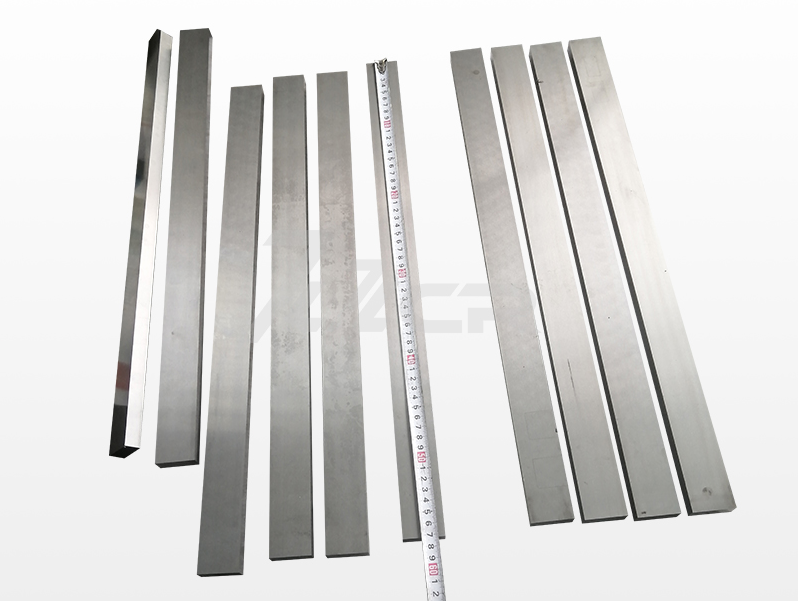

Enye yezinto eziningi zemichilo ye-tungsten Carbide, iqanjwe ngenxa yokwakheka kwayo okungunxande kwamapuleti (noma izigcawu), eyaziwa nangokuthi uTungsten Carbide strip / amapuleti. I-Tungsten Carbide Strip inobulukhuni obuhle, ukumelana okuhle, i-modulus ephezulu, amandla aphezulu apholile, ukuqina okuphezulu kwamakhemikhali (i-acid, i-coefficial ephezulu, ukuthuthuka okushisayo okufana ne-iron kanye ne-alloys yayo.

Yini izizathu zeukuthakazelayemichilo ye-tungsten carbide? I-Chuangrui Carbide izophendula ngokulandelayo:

.

(2)Ukuthakazelakuzokwenzeka futhi lapho i-ejenti ye-braziso ingakhethiwe futhi isetshenziswe ngokungafanele, isibonelo, lapho i-borax isetshenziswa njenge-ejenti ye-brazing, i-borax iqukethe ngempumelelo umswakama we-deoxiding ngoba i-borax iqukethe umswakama owengeziwe, futhiukuthakazelakwenzeka kwenzeka.

(3) Amazinga okushisa afanelekile kufanele abe ngu-30 ~ 50 ° C ngaphezulu kwephuzu lokuncibilika lensimbi ebhuqiwe, futhiukuthakazelakuzovela uma izinga lokushisa liphezulu kakhulu noma liphansi kakhulu. Ukushisa kakhulu kungadala i-oxidation eWeld. Usebenzisa insimbi equkethe i-zinc-equkethe i-brazing izonikeza i-weld umbala ohlaza okwesibhakabhaka noma omhlophe. Lapho izinga lokushisa le-brazing liphansi kakhulu, kuzokwakhiwa ama-weld akhulu, futhi ingaphakathi le-weld lizombozwa nge-porusity kanye nokuthambekela kwe-slag. Lezi zimo ezimbili ezingenhla zizonciphisa amandla e-weld, futhi kulula ukuqeda lapho kucinywa noma kusetshenziswe.

Isikhathi sePosi: Aug-28-2024