Izingxenye ze-MWD & LWD tungsten Carpide Poppe Poppep kanye ne-Orifice yamathuluzi okumba

Ukufanisa

Le khasiUTungsten Carbide Poppep ukugcinaKu-MWD ne-LWD kusetshenziselwa umsebenzi wokuvuselela, ukuvalwa kwesikhashana, ukugeleza, nokuthumela ingcindezi ye-slurry kanye neminye imininingwane emuva ngesiginali ye-pulse. I-Tungsten Carbide Main Valve Core ingenye yazo esetshenziswa ku-MWD ne-LWD. Ukucaciswa okuhlukile kwesisekelo se-valve esemqoka kungakhiqiza amasiginali wengcindezi ehlukene, kulula ukulungisa amandla okucindezela kwesiginali ngokuya ngezimo ezinhle, ukujula kahle nezinye izinto.

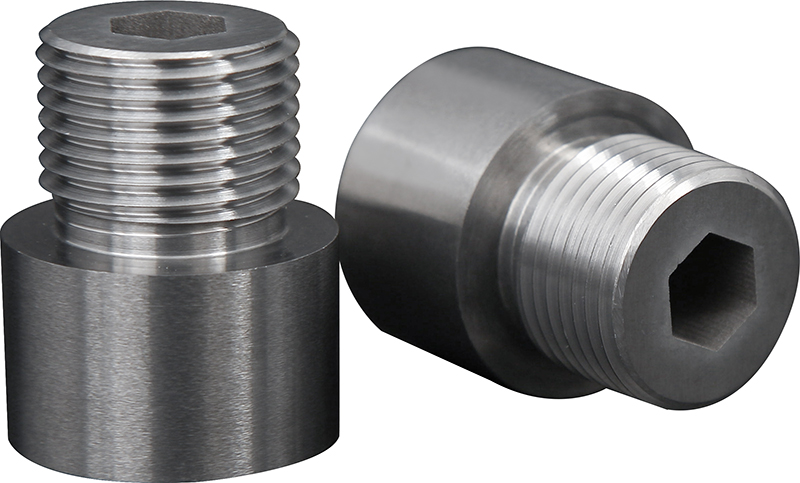

Ifektri yethu isebenzisa izinto ezisezingeni eliphakeme ze-Chinese Brand ukukhiqiza i-Poppet Tip qinisekisa ukumelana kwe-Fear.I-Carbide Poppet end Imprets Hip umfaniswano wokulinganisa. Thuthukisa amandla okugoba nokuphila kokukhathala kwe-carbide.

Inqubo yethu yokuqeda ukuqeda i-CNC Semi-ukuqeda iqinisekisa ukuthi wonke ama-poppet end akhiqizwa ngokunemba okukhulu. Le ndlela elawulwa ama-machina alawulwa yikhompyutha iqinisekisa ubukhulu obungaguquki, ukuqeda okubushelelezi, nokubekezelelana okuqinile, okuholela kumkhiqizo onamathela ngokuphelele kwiKhasimende elidingayo.

Ipharameter

Ukuphela kwe-poppet kwenziwatU-Ungsson CarbideIzinto ezibonakalayo.Ingxenye yengxenye ye-popped ye-popped ingukunemba komhlaba usebenzisa idatha ye-CNC yokunemba. Le nqubo yokukhiqiza eyiphutha iqinisekisa ukunemba okuphezulu kakhulu nokungaguquguquki ku-Thringing. Ngaleli zinga lokunemba, ungabethemba ukuthi i-Poppep Tip ngayinye izolingana nomthungo kumishini yakho yokumba.Iqembu elinolwazi lingashintsha imicu yangaphakathi kwizidingo zakho zokudweba, ukuqinisekisa ukuthi i-poppet iyisifanele esifanele samathuluzi akho.

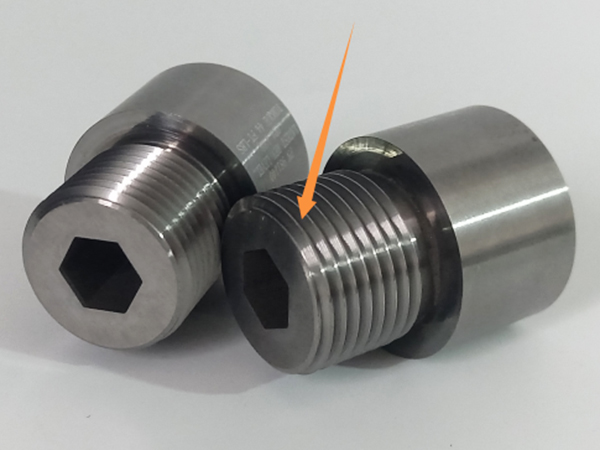

Ukumaka kwe-laser ukuthola ukuqinisekiswa kosayizi okusheshayo nokulandela umkhondo.

Ukucacisa

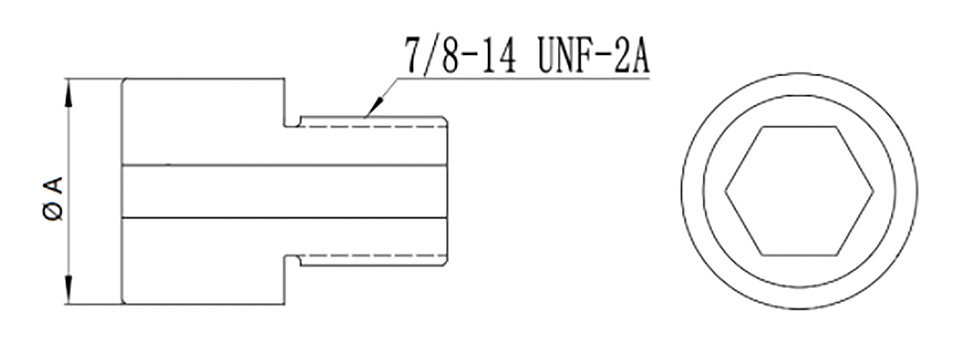

I-Carbide Poppep End

| Into yendaba | Usayizi we-OD | Intanjana |

| 981213 | Ø1.086 '' | 7/8-14 Aff-2A |

| 981214 | Ø1.040 '' | 7/8-14 Aff-2A |

| 981140 | '122 | 7/8-14 Aff-2A |

Ngezinketho eziningi zosayizi ezitholakalayo, ezisukela ku-OD1.086 '', 1.040 '', 1.122 '', futhi singakwamukela ngokwenziwe ngokwezidingo zamakhasimende. Futhi ngaphezulu, ungathola ukulungele okulungele izidingo zakho zamathuluzi.

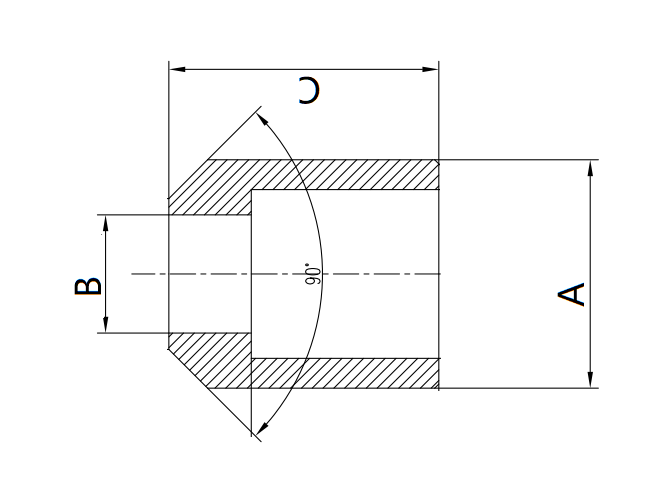

Izeluleko ze-Carbide Poppep yezeluleko ze-P360

| Dlala impi | Øb | Ø |

| I-1.04 '' | 0.57 '' ' | 1.30 '' |

| I-1.086 '' | 0.57 '' ' | 1.30 '' |

| 1.125 '' ' | 0.57 '' ' | 1.30 '' |

| 1.16 '' | 0.57 '' ' | 1.30 '' |

I-Carbide Poppep Amanye amabanga alandelayo:

| Ithathe | Izakhiwo Ezibonakalayo | Isicelo esikhulu nezimpawu | ||

| Ubunzima | Incekusana | Trs | ||

| Hra | g / cm3 | N / mm2 | ||

| I-CR35 | 88.5-89.5 | 14.30-14.50 | ≥2800 | Kufanelekile ukukhiqiza ama-bushings wezithombe nama-nozzles ngenxa yobulukhuni obuphezulu nokumelana okuhle kokuvinjelwa, |

| I-CR06N | 90.2-91.2 | 14.80-15.00 | ≥2560 | Kufanelekile ukukhiqiza imikhono kanye nama-bushings asetshenziswa embonini kawoyela negesi ngenxa yokugqwala okuhle nokuguguleka, |

Izinzuzo zethu

● Ukulethwa okufushane futhi ngokulethwa kwezikhathi

● Usayizi ophezulu wokucaciswa olawulwa

● Ukumelana okuhle kokugqoka

Izinsizakalo zethu

● Isitifiketi sebanga

● ubukhulu nokuhlolwa kwezinto ezibonakalayo nokuvunywa

● Ukuhlaziywa kwamasampula kuyatholakala

Ungahle futhi uthande

Ithiphu Poppep

Indandatho yokuqinisa

I-Servo Orifice Pulser

I-Orifice ye-Pulser ejwayelekile 350/650

Imishini yokukhiqiza

Ukugaya okumanzi

Spray eyomile

Gcinezela

I-TPA Press

Semi-Press

I-Hip enetho

Ukusebenza kwemishini

Okokumbaya

Ukusika ucingo

Ukugaya okuqondile

Ukugaya kwendawo yonke

Ukugaya kwendiza

Umshini we-CNC milling

Ithuluzi lokuhlola

Imitha ye-hardness

Umdlandla

Isilinganiso se-Quadratic element

Ithuluzi le-Cobalt Magnetic

I-MicrosCrographic DimcroScope