Imimese yezimboni ye-tungsten Carbide yezimboni

Ukufanisa

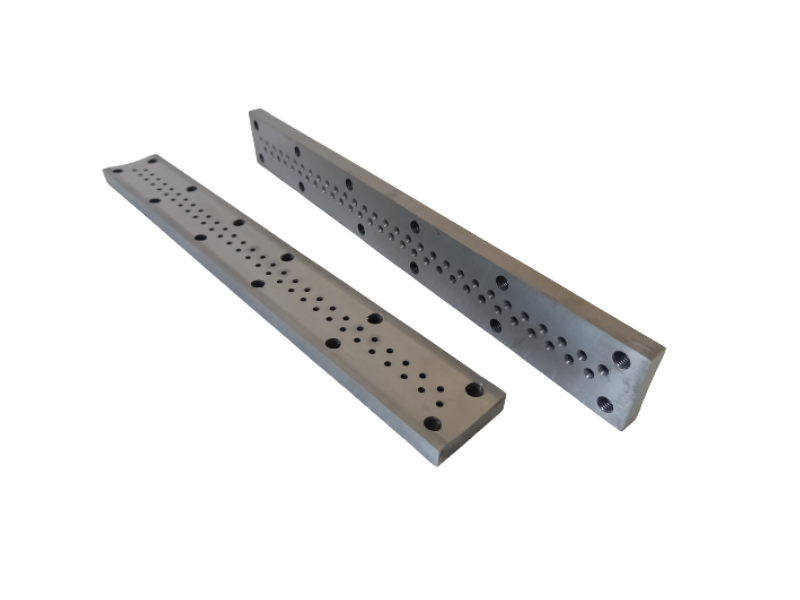

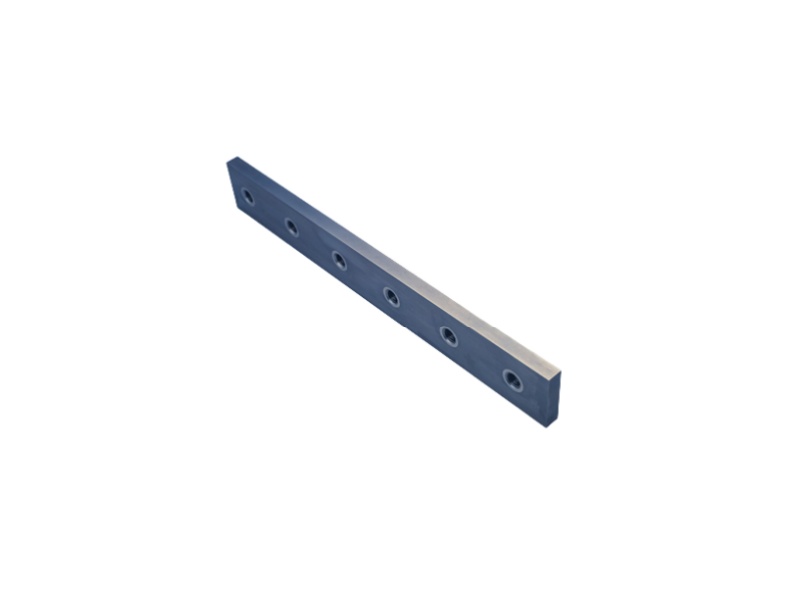

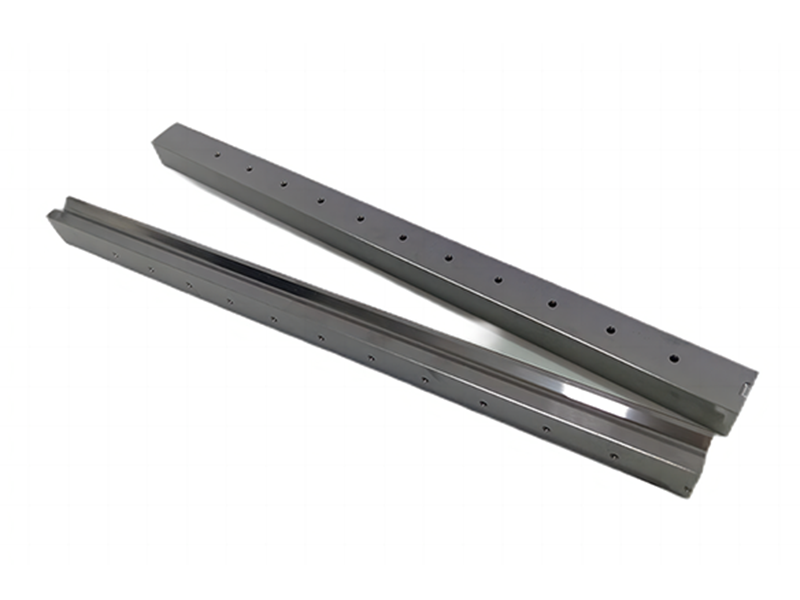

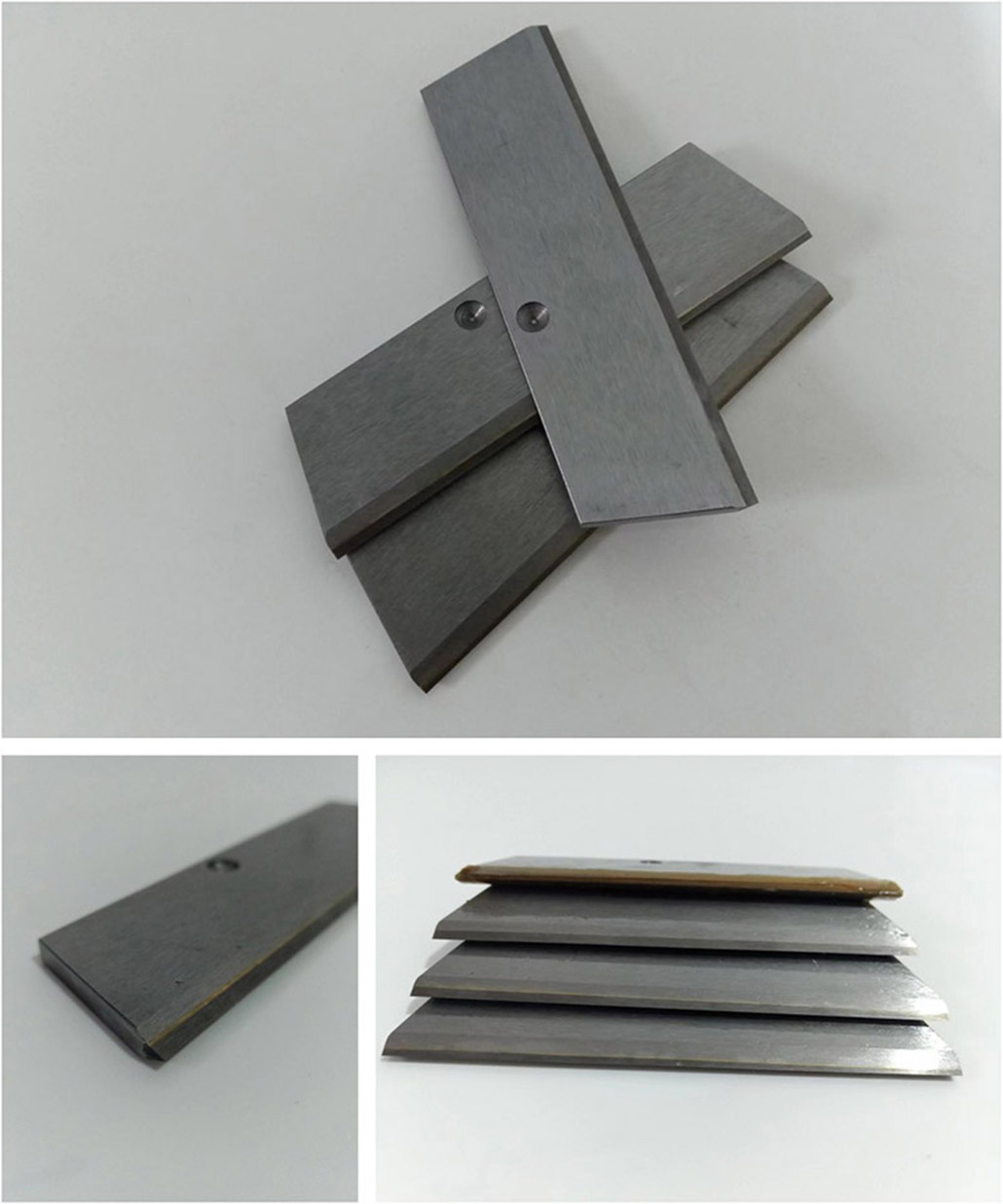

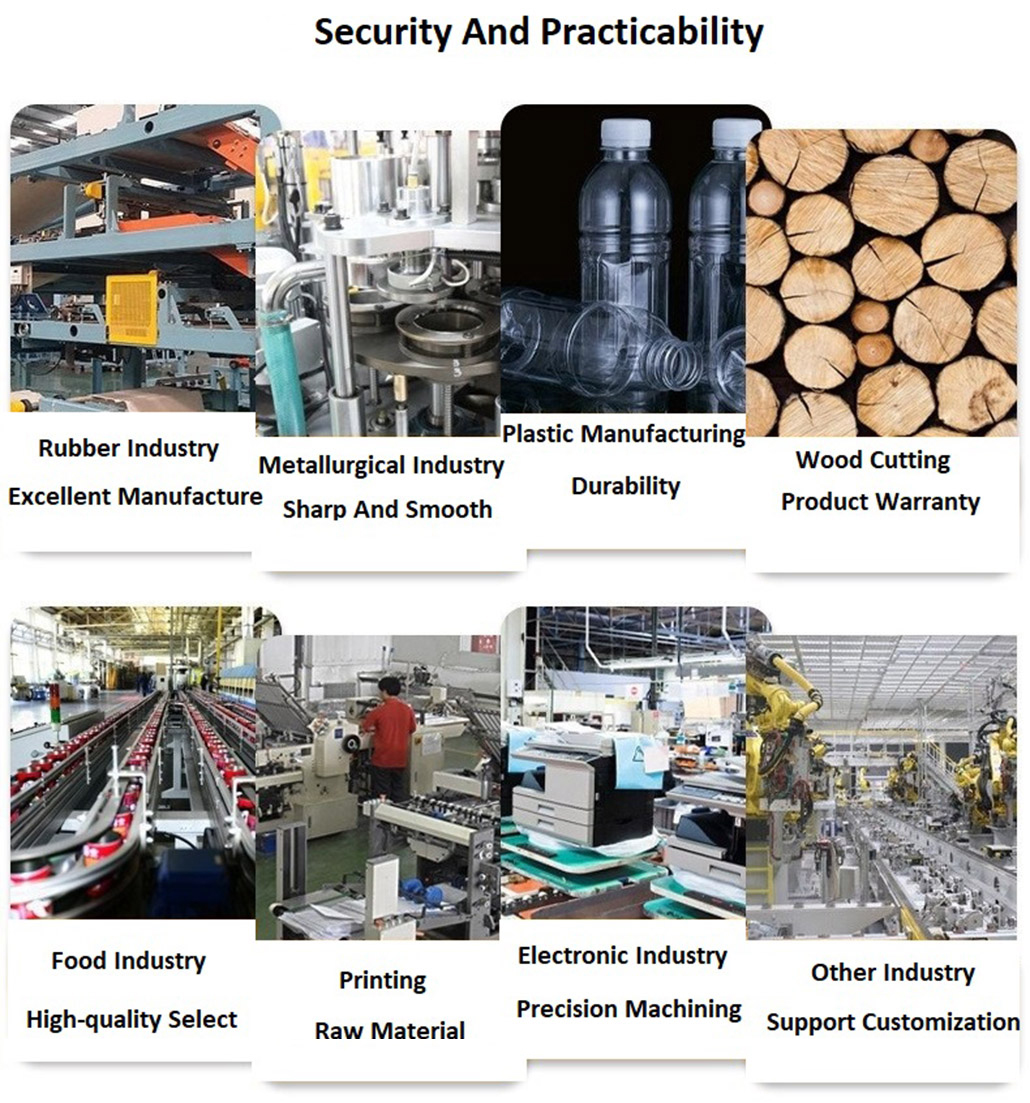

Imimese yezimboni ye-Tungsten Carbide kanye nama-blade anobulukhuni futhi agqoke ukumelana, usayizi owenziwe ngezifiso nebanga ayamukelekile. Okusetshenzisiwe ezimbonini eziningi, njengokufakwa kwamaphakeji, ibhethri le-li-ion, ukucubungula insimbi, ukuphinda usebenzise kabusha, ukwelashwa nokunye.

Izici

• Izinto zokwakha ze-Carbide zoqobo zangempela

• Ukucacisa imininingwane & isiqinisekiso sekhwalithi

• Gcina i-blade ibukhali ngokuqina okuhlala isikhathi eside

• Izinsizakalo zefekthri engochwepheshe kanye nemikhiqizo ebiza kakhulu

• Amasayizi ahlukahlukene namamaki wohlelo ngalunye

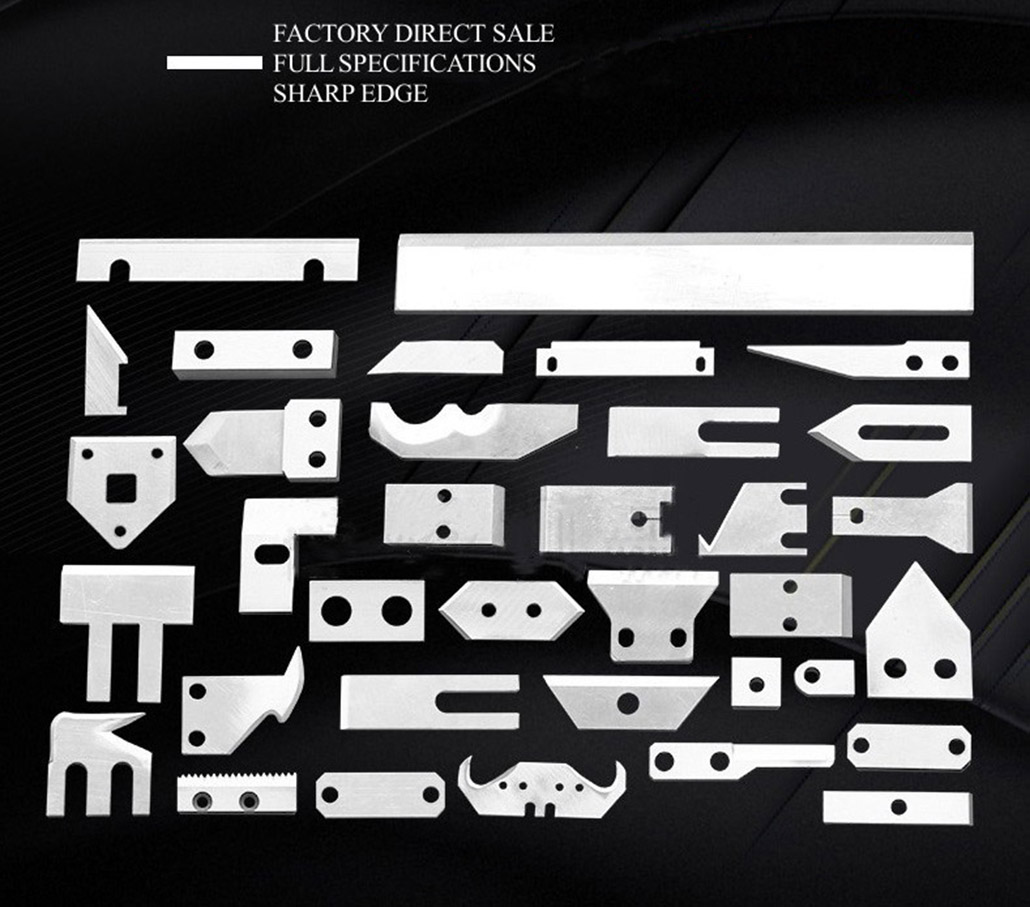

Ibanga lemimese ye-tungsten Carbide ne-blade

| Khuphuka | Usayizi wokusanhlamvu | Co% | Ubulukhuni (HRA) | Ubuningi (G / CM3) | Trs (n / mm2) | Isicelo |

| Ucr06 | Uktrafine | 6 | 93.5 | 14.7 | 2400 | Ibanga le-Alloy le-Ultrafine elinobulukhuni obuphezulu nokugqoka ukumelana. |

| Ucr12 | 12 | 92.7 | 14.1 | 3800 | ||

| ISCR06 | Imithumisi | 6 | 92.9 | 14.9 | 2400 | Ibanga le-Submicron Alloy elinobulukhuni obuphezulu nokugqoka ukumelana. |

| ISCR08 | 8 | 92.5 | 14.7 | I-2600 | ||

| SCR10 | 10 | 91.7 | 14.4 | 3200 | Ibanga le-allwoy le-submicn ngobulukhuni obuphezulu nobunzima obuphezulu, elilungele izinhlelo ezihlukile zezimboni zezimboni.such njengephepha, indwangu, amafilimu, izinsimbi ezingezinhle njll. | |

| ISCS15 | 15 | 90.1 | 13.9 | 3200 | ||

| MCR06 | Okuphakathi | 6 | 91 | 14.9 | 2400 | Ibanga le-Alley eliphakathi nobulukhuni obuphezulu nokugqoka ukumelana.Kufanele ukumelana nokusika kwezimboni kanye namathuluzi okuchoboza ngaphansi kwezimo zomthelela ophansi. |

| MCR08 | 8 | 90 | 14.6 | 2000 | ||

| MCR09 | 9 | 89.8 | 14.5 | I-2800 | ||

| MCR15 | 15 | 87.5 | 14.1 | 3000 | Ibanga le-alloy eliphakathi elinobunzima obuphezulu Inobunzima obuhle nokumelana nomthelela. |

Omunye umkhiqizo ongawuthanda

I-carbide ekhethekile ye-carbide ekhethekile

Imimese yepulasitiki ye-carbide kanye nerabha

Carbide Plasting Film Cutting Knife

Carbide ukugunda ummese oshelelayo

Imimese eyisikwele ye-carbide squed

Carbide strip blade nge hole

I-adazulu

• Ngaphezu kweminyaka engu-15 isipiliyoni sokukhiqiza esikhiqizayo nemishini esezingeni eliphezulu nobuchwepheshe.

• Ukugqwala okuphezulu nokumelana nokushisa; Ukusika okuhle kakhulu kwempilo ende.

• Ukunemba okuphezulu, ukusika okusheshayo, ukuqina nokusebenza okuzinzile.

• I-Mirror Polishing Place; Yeqa ukusika okujwayelekile kokunciphisa isikhathi esingaphansi.

Izinja

Imimese ye-Carbide yaseTungsten kanye nama-blades wokusika nokugcotshwa kokupakisha, ukusika, kanye nemicibisholo eminye imishini esetshenziswa ekudleni, ephepheni, ugwayi, izindwangu, ifenisha kanye nezimboni zensimbi, phakathi kwabanye abaningi.

Ukulawulwa Kwekhwalithi Yethu

Umgomo

Ikhwalithi ingumphefumulo wemikhiqizo.

Gxila ngokuqinile.

Zero ukubekezelela amaphutha!

Kudlule isitifiketi se-iso9001-2015

Imishini yokukhiqiza

Ukugaya okumanzi

Spray eyomile

Gcinezela

I-TPA Press

Semi-Press

I-Hip enetho

Ukusebenza kwemishini

Okokumbaya

Ukusika ucingo

Ukugaya okuqondile

Ukugaya kwendawo yonke

Ukugaya kwendiza

Umshini we-CNC milling

Ithuluzi lokuhlola

Imitha ye-hardness

Umdlandla

Isilinganiso se-Quadratic element

Ithuluzi le-Cobalt Magnetic

I-MicrosCrographic DimcroScope