Ipuleti le-Carbide Plate for Mold

Ukufanisa

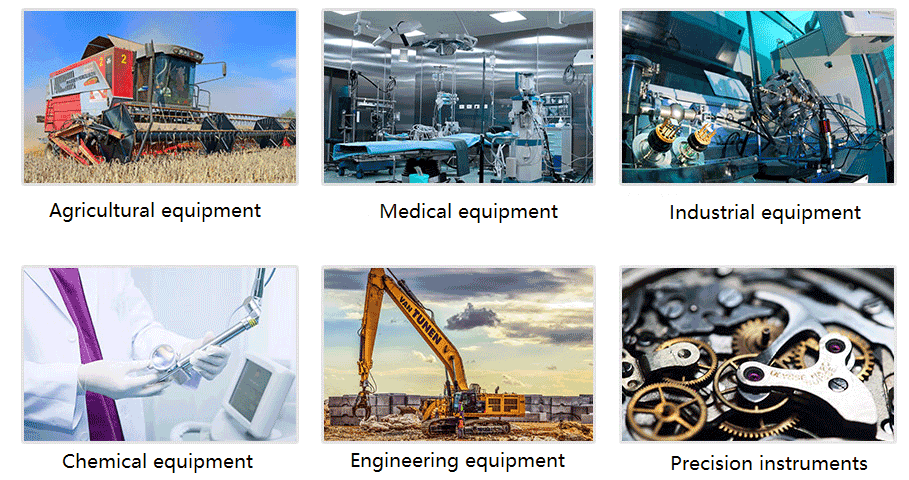

Iplate ye-Carbide yeTungsten Carbide enokuqina okuhle nokumelana nomthelela oqinile, ingasetshenziswa ku-Hardware nasezitembu ezijwayelekile zifa.

Ipuleti ye-Carbide yeTungsten isetshenziswa kabanzi embonini ye-elekthronikhi, i-rotor yemoto, i-stator, ifreyimu eholayo ye-LED, amanye amabhlogo we-tungsten carbide kumele ahlolwe ngokuqinile futhi kuphela ngaphandle kwalabo okulimazayo, ama-bubble, imifantu, njll. Kungathunyelwa ngaphandle.

Kungani ukhethe iTungsten Carbide Material?

ICarbide efakwe ngoCement inochungechunge lwezakhiwo ezinhle kakhulu ezinjengobulukhuni obuphezulu, gqoka ukumelana, amandla amahle kanye nokuphikisana nokushisa, ngisho nokuvikelwa okuphezulu, futhi kusenokubumbana okuphezulu ngo-1000 ° C. Ngakho-ke, isetshenziswa kabanzi emishini. Izakhiwo ezibonakalayo ze-tungsten Carbide okungenani izikhathi ezi-3 zensimbi. Kungenziwa zonke izinhlobo zamapuleti e-carbide.

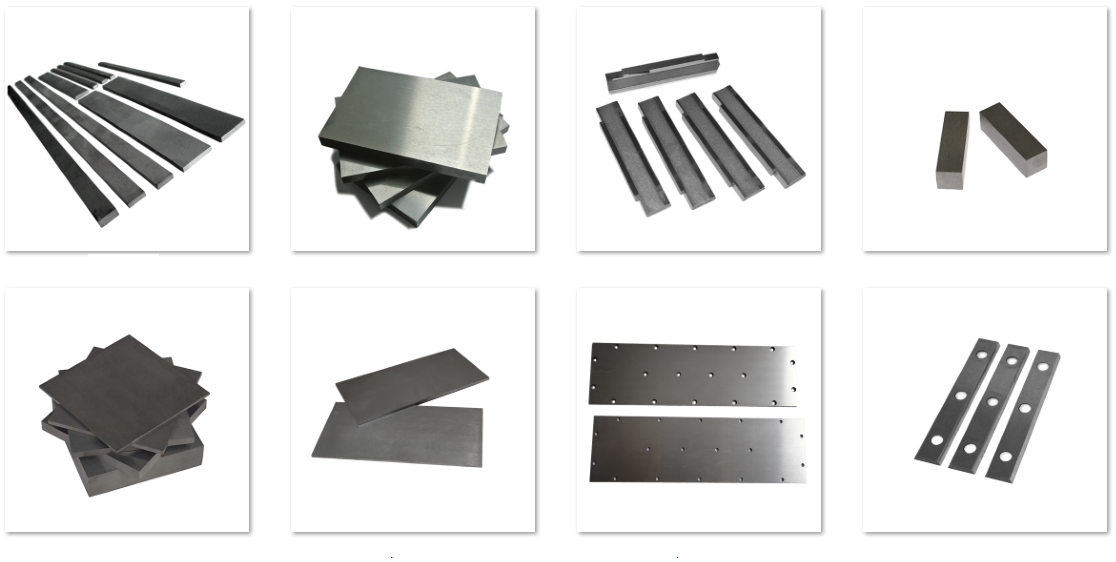

Izithombe zesethenjwa

Imininingwane kasayizi ejwayelekile: (OEM wamukelwa)

| Ukujiya | Ububanzi | Ubude |

| 1.5-2.0 | I-150 | -Mashumi |

| 2.0-3.0 | -Mashumi | 25 |

| 3.0-4.0 | 25 | I-600 |

| 4.0-6.0 | 300 | I-600 |

| 6.0-8.0 | 300 | 800 |

| I-8.0-10.0 | 300 | Okungama-750 |

| 10.0-14.0 | -Mashumi | I-650 |

| > 14.0 | -Mashumi | 500 |

Izinja

Ikusasa likaChuangrui eline-carbide Plate future

1. Ukuqina okuhle kakhulu okushisayo kanye nokuphikiswa okuphezulu kokushisa kwezinga lokushisa.

2. Izinga lokushisa eliphakeme eliphakeme emazingeni okushisa aphezulu.

3. Ukumelana okuhle okushisayo.

4. Ukusebenza okuphezulu okushisayo.

5. Ikhono elihle kakhulu lokulawula i-oxidation.

6. Ukumelana nokugqwayiza emazingeni okushisa aphezulu.

7. Ukumelana kahle kokugqwala kwamakhemikhali.

8. Ukumelana kakhulu kwe-abrasion.

9. Impilo ende yenkonzo.

Uyemukelwa ukuxhumana nathi nganoma yisiphi isikhathi!

Imishini yokukhiqiza

Ukugaya okumanzi

Spray eyomile

Gcinezela

I-TPA Press

Semi-Press

I-Hip enetho

Ukusebenza kwemishini

Okokumbaya

Ukusika ucingo

Ukugaya okuqondile

Ukugaya kwendawo yonke

Ukugaya kwendiza

Umshini we-CNC milling

Ithuluzi lokuhlola

Imitha ye-hardness

Umdlandla

Isilinganiso se-Quadratic element

Ithuluzi le-Cobalt Magnetic

I-MicrosCrographic DimcroScope