Izinduku ze-tungsten carbide

Ukufanisa

Izinduku ze-tungsten Carbide zisetshenziselwa kabanzi ngamathuluzi aphezulu we-carbide aqinile afana nabasiki bokugaya, ukuqeda amamitha, ama-drill, ama-reamer; Ukunyathela, amathuluzi wokulinganisa nezingxenye ezahlukahlukene zokugqoka.

Ukucaciswa kwezinduku ze-tungsten Carbide

Izinhlobo zezinduku ze-carbide:

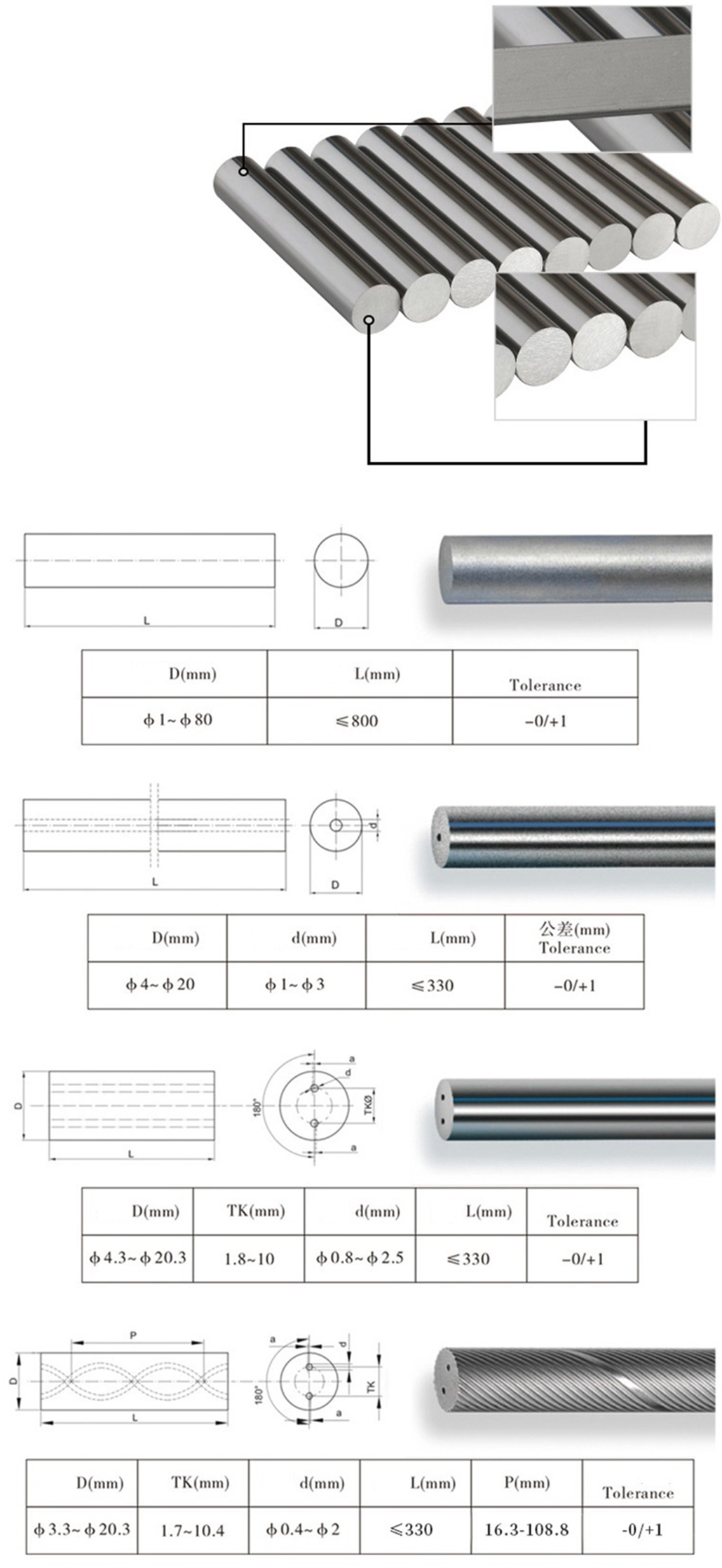

I-Carbide Rod Rod eqinile eqediwe & induku ye-carbide ingenalutho

Induku ye-Carbide enezimbobo ezi-coolant eziqondile eziqondile

Izinduku ze-Carbide ezinezimbobo ezimbili eziqondile ezipholile

Izinduku ze-Carbide ezinezimbobo ezimbili ezipholile ezingenampilo.

Ubukhulu obuhlukahlukene buyatholakala, izinsizakalo zokwenza ngokwezifiso zamukelekile

Khuphuka

| Ibanga le-ISO | Usayizi wokusanhlamvu (μm) | Co% | Ubulukhuni (HRA) | Ubuningi (G / CM3) | Trs (n / mm2) | Izimboni Zezicelo | Isicelo |

| K05-k10 | 0.4 | I- | 94 | 14.8 | 3800 | Imboni ye-PCB | Insimbi engagqwali, insimbi engeyona eyenhlamvu, impahla eyinhlanganisela ne-PCB cutter |

| K10-K20 | 0.4 | 8.5 | 93.5 | 14.52 | 3800 | Amathuluzi wokusika we-PCB; Izinto ezisetshenziswayo zepulasitiki nobunzima obuphezulu | |

| K10-K20 | 0.2 | 9.0 | 93.8 | 14.5 | 4000 | Umkhakha Wokubumba | Ukuqina okuphezulu |

| K20-K40 | 0.4 | 12.0 | 92.5 | 14.1 | 4200 | Imboni ye-3C ne-Mold | Ukusika insimbi (HRC45-55) Al alloy ne-TI alloy |

| K20-K40 | 0.5 | 10.3 | 92.3 | 14.3 | 4200 | I-alloy engenacala ne-heastration arvinant, i-iron iron | |

| K20-K40 | 0.5 | 12.0 | 92 | 14.1 | 4200 | Insimbi engagqwali, i-iron iron kanye nokuqina okuphezulu | |

| K20-K40 | 0.6 | 10.0 | 91.7 | 14.4 | 4000 | I-alloy yensimbi engenacala neyokumelana ne-ally, i-cast iron nensimbi ejwayelekile | |

| K30-K40 | 0.6 | 13.5 | 90.5 | 14.08 | 4000 | Ukuncipha kokunemba kuyafa | Ukwenza i-punch eyindilinga |

| K30-K40 | 1.0-2.0 | 12.5 | 89.5 | 14.1 | I-3600 | Ukwenza i-Puch ethambile | |

| K30-K40 | 1.5-3.0 | 14.0 | 88.5 | 14 | 3700 |

Izici

● I-100% izinto eziyizintombi tungsten Carbide

● Umhlaba kanye nomhlabathi womabili uyatholakala

● Amasayizi ahlukahlukene namamaki; Izinsizakalo Zezifiso

● Ukumelana kahle nokuqina

● Amanani ancintisanayo

Induku ye-Carbide ehlanganisiwe yamathuluzi okusika

Kuqediwe izinduku zensimbi eTungsten

Ibha ye-tungsten Carbide Round Bar

Carbide Carbide Micro Rod

I-Blank Tarbsten Carbide Rod

Umkhiqizi we-Carbide Rod

Imbuyiselo

● Usayizi wokusanhlamvu kusuka ku-0.2μm-0.8μm, ubulukhuni 91hra-95hhhhra. Ngokuhlolwa kwekhwalithi okuqinile futhi uqinisekise ikhwalithi engaguquki i-batch ngayinye.

● Okukhethekile ku-Carbide Rod iminyaka engaphezu kwe-10, ngomugqa womkhiqizo ovelele wezinduku ze-carbide eziqinile nenduku enezimbobo ezipholile.

● Njengomenzi we-ISO, sisebenzisa izinto ezisezingeni eliphezulu ukuqinisekisa ikhwalithi nokusebenza okuhle kwezinduku zethu ze-carbide.

● Induku ye-carbide iyinto eluhlaza yokwenza amathuluzi okusika. Amathuluzi akwenziwe kithi anesikhathi eside sokuphila nokusebenza kwemishini ezinzile.

Isicelo

I-Tungsten Carbide Rod kabanzi emikhakheni eminingi, njengasephepheni, emaphaketheni, okuphrinta, nokungemisi izimboni zokucubungula zensimbi zensimbi; imishini, amakhemikhali, i-petrolleum, i-metallum, imboni yokubumba. Nemboni yemoto & yezithuthuthu, imboni ye-elekthronikhi, imboni ye-compressors, imboni ye-aerospace, izimboni zokuvikela.

Ukulawulwa Kwekhwalithi Yethu

Umgomo

Ikhwalithi ingumphefumulo wemikhiqizo.

Gxila ngokuqinile.

Zero ukubekezelela amaphutha!

Kudlule isitifiketi se-iso9001-2015

Imishini yokukhiqiza

Ukugaya okumanzi

Spray eyomile

Gcinezela

I-TPA Press

Semi-Press

I-Hip enetho

Ukusebenza kwemishini

Okokumbaya

Ukusika ucingo

Ukugaya okuqondile

Ukugaya kwendawo yonke

Ukugaya kwendiza

Umshini we-CNC milling

Ithuluzi lokuhlola

Imitha ye-hardness

Umdlandla

Isilinganiso se-Quadratic element

Ithuluzi le-Cobalt Magnetic

I-MicrosCrographic DimcroScope