inkinobho ye-tungsten carbide spherical

Ukufanisa

Amazinyo we-Carbide Carbide Carbive asetshenziswa kabanzi asetshenziswa kabanzi kwimishini yokugembula yeqhwa yokushayela kawoyela nokususwa kweqhwa. Ngaphezu kwalokho, amazinyo we-carbide carbide ball futhi asetshenziswa kahle kumathuluzi wokusika kanye nemishini yezimayini, ukulungiswa komgwaqo namathuluzi okumba amalahle. Amazinyo we-Carbide Carbide Carbide Carbide asetshenziswe ezimayini ikakhulukazi asetshenziswa njengamathuluzi okusojika, izimayini, tuniliseling kanye nezakhiwo zomphakathi.

Isicelo

Inkinobho ye-carbide efakwe ngocent isetshenziswa kabanzi ekuvuthweni kwensimu yamafutha kanye nokususwa kweqhwa, ukulima kweqhwa noma kweminye imishini ngenxa yezakhiwo zazo ezihlukile. Ngokusho kwemishini ehlukene yokumba, njengezimbizo ze-CONE, ama-Dth bits, amathuluzi okumba emoyeni, amazinyo we-carbide ball ahlukaniswe ngamaphethini ajwayelekile: p-flat top indawo, isikhundla sebhola le-z-coin, isikhundla se-sedge. Ukuqina nobuchwepheshe obuphezulu kuqinisekisa ikhwalithi ephezulu yemikhiqizo yethu, amazinyo ebhola e-carbide bavame ukusetshenziswa njengamathuluzi okumba izimpesheni, amathuluzi wemishini yezimayini namathuluzi wokulungiswa kwemigwaqo eqhweni kanye nokuhlanza umgwaqo. Amazinyo e-Carbide Carbide Carbide asetshenziswa futhi asetshenziswa kabanzi njengethuluzi lokumbika ngokugqwala, ukumbiwa, ukumbiwa kwethanga kanye nezakhiwo zomphakathi. Ngaphezu kwalokho, isetshenziswa futhi njengokufaneleka okuncane kwe-rock hound-duty rock drill noma ithuluzi lokushayela elijulile elifanele.

Izici

I-Carbide efakwe ngoCement iyinto engcono kakhulu yokukhiqiza amazinyo we-carbide carbide ibhola asetshenziswa kabanzi embonini yokumba ngesampula yesampula.

Inkinobho ye-Carbide isetshenziswa kabanzi embizeni, ekotina nokusika ngenxa yobulukhuni bayo obuphakeme. Zingasetshenziswa futhi ku-high high raterator bits.

Khuphuka

| Khuphuka | Incekusanag / cm3 | Trs MPA | UbunzimaHra | Isicelo |

| I-CR4C | 15.10 | 1800 | 90.0 | Isetshenziselwa ikakhulukazi ukusika izinto ezinzima nezithambile zomthelela wokushayela umthelela. |

| CR6 | 14.95 | 1900 | 90.5 | Kusetshenziswa njengezinyoni zamalahle kagesi, ukukhethwa kwamalahle, ama-petroleum cone bits kanye nama-scraper ibhola-izinyo lebhola. |

| Cr8 | 14.80 | I-2200 | 89.5 | Kusetshenziswe njengokushayela okuyisisekelo, ukushayela kwamalahle kagesi, ukukhethwa kwamalahle, ukushayela kukaphethiloli kanye nokushayela kwebhola le-scraper. |

| I-CR8C | 14.80 | 2400 | 88.5 | Ngokuyinhloko esetshenziswa njengezinyo lebhola lomthelela omncane nomthelela omncane futhi ophethe isihlahla somshini wokuhlola ojikelezayo. |

| CR11C | 14.40 | I-2700 | 86.5 | Iningi lisetshenziswa ekushayweni komthelela nakwi-cone drill ukusika amazinyo ebhola lezinto zokwakha ezilukhuni. |

| I-CR13C | 14.2 | I-250 | 86.5 | Isetshenziselwa ikakhulukazi ukusika amazinyo ebhola wezinto zokwakha bunzima eziphakathi nendawo eziphakeme ekushayweni komthelela we-rotary umthelela. |

| I-CR15C | 14.0 | 3000 | 85.5 | Isetshenziselwa amathuluzi kawoyela amancane namathuluzi wokusika aphakathi nendawo aphakathi nendawo. |

Ubungako

I-OEM yamukelwa.

Usayizi ojwayelekile wenkinobho ye-tungsten carbide njengoba ngezansi:

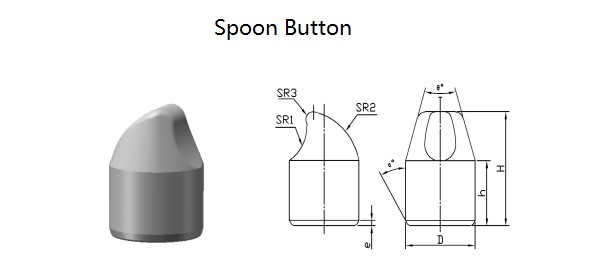

| Ukuthayipha | Ubukhulu (mm) | ||||||||

| D | H | h | Ɵ ° | Sr1 | Sr2 | SR3 | α ° | e | |

| S1015 | 10.25 | 15 | 9.8 | 50 | 12 | 20 | + | 18 | 1.2 |

| S1116 | 11.3 | 16.5 | 10.2 | 50 | 15 | 24 | + | 18 | 1.2 |

| S1218 | 12.35 | 18 | 11 | 36 | 20 | 25 | 2,5 | 18 | 1.5 |

| S1319 | 13.35 | 19 | 12 | 50 | 15 | 20 | + | 18 | 1.5 |

| S1421 | 14.35 | 21 | 12.5 | 40 | 12 | 25 | + | 18 | 1.8 |

| S1521 | 15.35 | 21 | 12 | 50 | 20 | 30 | + | 18 | 1.8 |

| S1624 | 16.35 | 24 | 13 | 30 | 15 | 20 | + | 18 | 2 |

| S1827 | 18.25 | 27 | 14.5 | 30 | 18 | 20 | + | 18 | 2 |

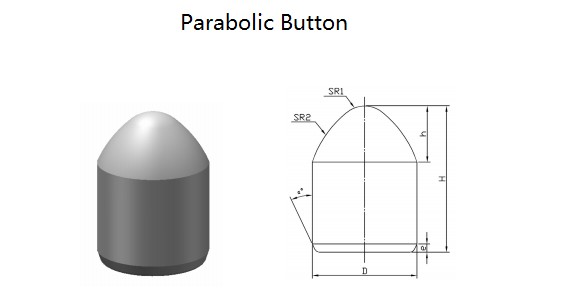

| Ukuthayipha | Ubukhulu (mm) | |||||||

| D | H | Sr1 | Sr2 | h | α ° | β ° | e | |

| D0711 | 7.25 | 11 | 1.9 | 8.7 | 3.9 | 20 | 25 | 1.6 |

| D0812 | 8.25 | 12 | 2,5 | 9 | 4.5 | 20 | 25 | 1.6 |

| D0913 | 9.25 | 13 | 2,5 | 11 | Okuthengwa edolo | 20 | 25 | 1.8 |

| D1015 | 10.25 | 15 | 3.2 | 11.8 | Okuthengwa edolo | 20 | 25 | 1.8 |

| D1117 | 11.3 | 17 | + | 13.5 | 6 | 20 | 25 | 1.8 |

| D1218 | 12.35 | 18 | + | 12 | 6.5 | 20 | 20 | 2 |

| D1319 | 13.35 | 19 | I-3.5 | 13.5 | 7.1 | 20 | 20 | 2 |

| D1420 | 14.35 | 20 | 4.2 | 13 | 8 | 20 | 20 | 2 |

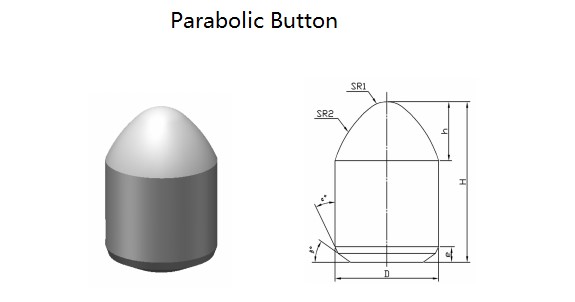

| Ukuthayipha | Ubukhulu (mm) | ||||||

| D | H | Sr1 | Sr2 | h | α ° | e | |

| D0711A | 7.25 | 11.0 | 1.9 | 8.7 | 3.9 | 18 | 1 |

| D0812A | 8.25 | 12.0 | 2,5 | 9 | 4.5 | 18 | 1 |

| D0913A | 9.25 | 13.0 | 2,5 | 11 | Okuthengwa edolo | 18 | 1 |

| D1015a | 10.25 | 15.0 | 3.2 | 11.8 | Okuthengwa edolo | 18 | 1.2 |

| D1117a | 11.3 | 17.0 | + | 13.5 | 6 | 18 | 1.2 |

| D1218A | 12.35 | 18.0 | + | 12 | 6.5 | 18 | 1.5 |

| D1319A | 13.35 | 19.0 | I-3.5 | 13.5 | 7.1 | 18 | 1.5 |

| D1420A | 14.35 | 20.0 | 4.2 | 13 | 8 | 18 | 8 |

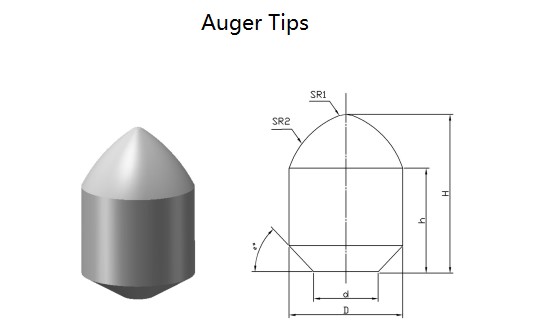

| Ukuthayipha | Ubukhulu (mm) | |||||

| D | d | H | h | Sr1 | Sr2 | |

| JM1222 | 12 | I-3.0 | 22 | 15 | 1.5 | 26 |

| JM1425 | 14 | I-4 | 25 | 17 | 1.5 | 26 |

| JM1625 | 16 | I-5 | 25 | 16 | 1.5 | 26 |

| JM1828 | 18 | I-5 | 28 | 18 | 1.5 | 26 |

| JM2428 | 24 | I-10.1 | 28 | 16 | 2 | 36 |

| JM2534 | 25 | 18.0 | 34 | 20 | - | 25 |

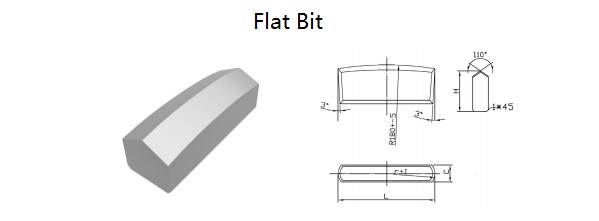

| Ukuthayipha | Ubukhulu (mm) | |||||

| L | H | C | r | |||

| A | B | C | ||||

| K026 | 26 | 18.0 | 15 | 12.5 | 8 | 13 |

| K028 | 28 | 18.0 | 15 | 12.5 | 8 | 14 |

| K030 | 30 | 18.0 | 15 | 12.5 | 8 | 15 |

| K032 | 32 | 18.0 | 15 | 12.5 | 8 | 16 |

| K034 | 34 | 18.0 | 15 | 12.5 | 8 | 17 |

| K036 | 36 | 18.0 | 15 | 12.5 | 10 | 18 |

| K038 | 38 | 18.0 | 15 | 12.5 | 10 | 19 |

| I-K040 | 40 | 18.0 | 15 | 12.5 | 10 | 20 |

| K042 | 42 | 18.0 | 15 | 12.5 | 10 | 21 |

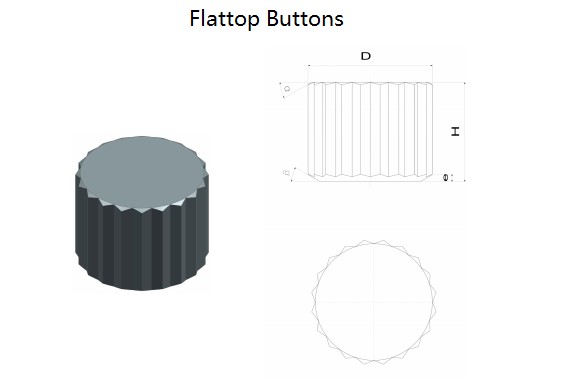

| Ukuthayipha | Ubukhulu (mm) | ||||

| D | H | t | α ° | e | |

| I-MH0806 | 8 | I- | 0.5 | 25 | 1.1 |

| MH1008 | 10 | 8.0 | 0.5 | 25 | 1.9 |

| MH1206 | 12 | I- | 0.5 | 25 | 1.9 |

| MH1208 | 12 | 8.0 | 0.5 | 25 | 2,5 |

| I-MH1410 | 14 | 10.0 | 0.5 | 25 | 2,5 |

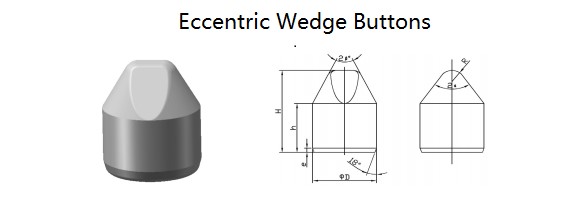

| Ukuthayipha | Ubukhulu (mm) | |||||||

| D | H | h | R | r | α ° | β ° | e | |

| I-X0810 | 8 | 10 | 6.5 | 2 | 1.8 | 45 | 22.5 | 1.5 |

| X1011 | 10 | 11 | Okuthengwa kwava + | 2,5 | 2 | 45 | 22.5 | 1.5 |

| X1013 | 10 | 13 | 9 | 2,5 | 2 | 45 | 22.5 | 1.5 |

| X1115 | 11 | 15 | 8 | 2.8 | 2,5 | 22.5 | 22.5 | 1.5 |

| X1215 | 12 | 15 | 9 | + | 2,5 | 45 | 22.5 | 1.5 |

| X1217 | 12 | 17 | 10.5 | I-3.5 | + | 35 | 20 | 1.5 |

| X1418 | 14 | 18 | 10 | I-3.5 | + | 45 | 22.5 | 1.5 |

| X1420 | 14 | 20 | 11 | I-2.7 | + | 35 | 22.5 | 1.5 |

| X1520 | 15 | 20 | 12 | + | + | 40 | 22.5 | 1.5 |

| X1621 | 16 | 21 | 11 | 2.6 | + | 35 | 22.5 | 2 |

| X1623 | 16 | 23 | 12 | + | I-3.5 | 30 | 18 | 2 |

| X1721 | 17 | 21 | 13 | 4 | I-3.5 | 40 | 22.5 | 2 |

| X1724 | 17 | 24 | 13 | I-3.5 | I-3.5 | 30 | 22.5 | 2 |

| X1929 | 19 | 29 | 17 | 4 | + | 30 | 15 | 2 |

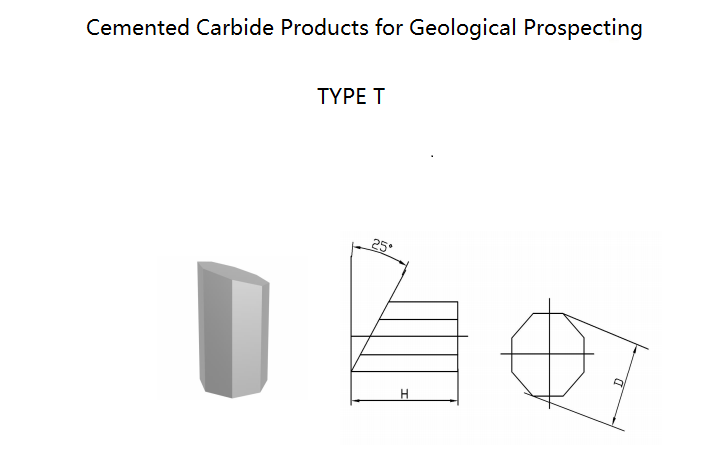

| Ukuthayipha | Ubukhulu (mm) | |

| D | H | |

| T105 | Okuthengwa edolo | 10 |

| T106 | Okuthengwa kwava + | 10 |

| T107 | Okuthengwa kwava + | 15 |

| T109 | 9 | 12 |

| T110 | 10 | 16 |

Izinzuzo zethu

Inkinobho ye-carbide enomthwalo we-Carned inokuvikeleka okuphakeme kakhulu kanye nokuqina komthelela, futhi inejubane lokumba eliphakeme kunemikhiqizo efanayo. Impilo engagadiwe kancanyana icishe ibe yizikhathi ezi-5-6 inqobo nje uma nje ine-diansiter efanayo, okuzuzisa ukonga amahora okusebenza asizi, ukunciphisa ijubane lezandla kanye nokusheshisa isivinini sobunjiniyela kanye nokusheshisa isivinini sobunjiniyela.

Ngemininingwane engaphezulu, wamukelekile ukuxhumana nathi nganoma yisiphi isikhathi!

Imishini yokukhiqiza

Ukugaya okumanzi

Spray eyomile

Gcinezela

I-TPA Press

Semi-Press

I-Hip enetho

Ukusebenza kwemishini

Okokumbaya

Ukusika ucingo

Ukugaya okuqondile

Ukugaya kwendawo yonke

Ukugaya kwendiza

Umshini we-CNC milling

Ithuluzi lokuhlola

Imitha ye-hardness

Umdlandla

Isilinganiso se-Quadratic element

Ithuluzi le-Cobalt Magnetic

I-MicrosCrographic DimcroScope