I-Tungsten Carbide Strips Cutter yokusika ngokhuni

Ukufanisa

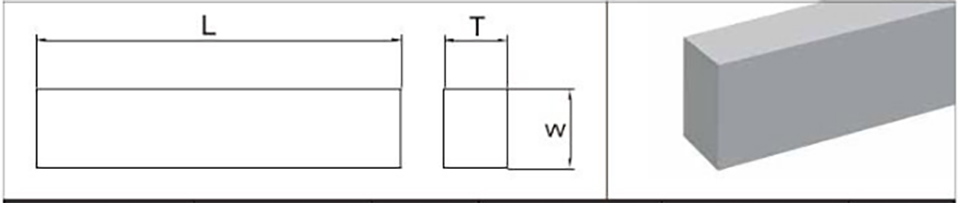

Imigoqo ye-tungsten Carbide Flat yenziwa ikakhulukazi kusuka ku-Wolfram Carbide nase-Cobalt powder ngezindlela ze-powder metallurgy. Inqubo enkulu yokukhiqiza yeTungsten Carbide Bar Stock iyi-powder milling, ibhola lokugaya, ukucindezela nangokona. Ngokusetshenziswa okuhlukile, okuqukethwe kwe-WC kanye ne-CO eTungsten Carbide Square Bar akufani. I-SOOL Carbide Carxangular bar isetshenziselwa ikakhulukazi ukucubungula i-iron empunga, izinto ezingezinhle zensimbi, insimbi evuthayo, i-PCB, i-brake for bar ingaqhutshwa futhi kumakhasimende amaklayenti, ukugaya, ukuthengisa.

Izinja

1. Isetshenziselwa ukwenza amathuluzi angenakuqhathaniswa. Njengemimese yemboni esebenza ngokhuni, imimese eqhekekile yeplastiki, njll.

2. Isetshenziselwa ukwenza izingxenye ezingamelana nezinyathelo zokushisa eziphezulu, izingxenye ezivimbela ukugqoka, izingxenye zokulwa nokuvikelwa. Njengomhlahlandlela kajantshi weThuluzi lomshini, ipuleti yokuqinisa i-anti-theft yokuqinisa komshini we-ATM, njll.

I-3. Isetshenziselwa ukwenza izingxenye ezivimbela ukugqokwa embonini yenjoloba nepulasitiki.

4. Isetshenziselwa ukwenza isikhunta.

I-5

Ukucacisa

Usayizi ojwayelekile njengoba ngezansi:

| Ukujiya | Ububanzi | Ubude | Ukujiya | Ububanzi | Ubude | ||||

| mm | mm Ukubekezela | mm | mm Ukubekezela | + 1.5mm Ukubekezela | mm | mm Ukubekezela | mm | mm Ukubekezela | + 1.5mm Ukubekezela |

| 2 | + 0.3 / 0.1 | 3 | + 0.4 / + 0.2 | I-310 | 3 | + 0.3 / 0.1 | 15 | + 0.6 / + 0.2 | I-310 |

| 2 | + 0.3 / 0.1 | 4 | + 0.4 / + 0.2 | I-310 | 3 | + 0.3 / 0.1 | 16 | + 0.6 / + 0.2 | I-310 |

| 2 | + 0.3 / 0.1 | 5 | + 0.4 / + 0.2 | I-310 | 3 | + 0.3 / 0.1 | 18 | + 0.6 / + 0.2 | I-310 |

| 2 | + 0.3 / 0.1 | 6 | + 0.4 / + 0.2 | I-310 | 3 | + 0.3 / 0.1 | 20 | + 0.6 / + 0.2 | I-310 |

| 2 | + 0.3 / 0.1 | 8 | + 0.4 / + 0.2 | I-310 | 3 | + 0.3 / 0.1 | 22 | + 0.6 / + 0.2 | I-310 |

| 2 | + 0.3 / 0.1 | 10 | + 0.4 / + 0.2 | I-310 | 3 | + 0.3 / 0.1 | 25 | + 0.6 / + 0.2 | I-310 |

| 2 | + 0.3 / 0.1 | 12 | + 0.4 / + 0.2 | I-310 | 3 | + 0.3 / 0.1 | 28 | + 0.6 / + 0.2 | I-310 |

| 2 | + 0.3 / 0.1 | 14 | + 0.4 / + 0.2 | I-310 | 3 | + 0.3 / 0.1 | 31 | + 0.6 / + 0.2 | I-310 |

| 2 | + 0.3 / 0.1 | 15 | + 0.4 / + 0.2 | I-310 | 4 | + 0.3 / 0.1 | 5 | + 0.6 / + 0.2 | I-310 |

| 2 | + 0.3 / 0.1 | 16 | + 0.4 / + 0.2 | I-310 | 4 | + 0.3 / 0.1 | 6 | + 0.6 / + 0.2 | I-310 |

| 2 | + 0.3 / 0.1 | 18 | + 0.4 / + 0.2 | I-310 | 4 | + 0.3 / 0.1 | 8 | + 0.6 / + 0.2 | I-310 |

| 2 | + 0.3 / 0.1 | 19 | + 0.4 / + 0.2 | I-310 | 4 | + 0.3 / 0.1 | 10 | + 0.6 / + 0.2 | I-310 |

| 3 | + 0.3 / 0.1 | 3 | + 0.4 / + 0.2 | I-310 | 4 | + 0.3 / 0.1 | 12 | + 0.6 / + 0.2 | I-310 |

| 3 | + 0.3 / 0.1 | 4 | + 0.4 / + 0.2 | I-310 | 4 | + 0.3 / 0.1 | 13 | + 0.6 / + 0.2 | I-310 |

| 3 | + 0.3 / 0.1 | 5 | + 0.4 / + 0.2 | I-310 | 4 | + 0.3 / 0.1 | 15 | + 0.6 / + 0.2 | I-310 |

| 3 | + 0.3 / 0.1 | 6 | + 0.4 / + 0.2 | I-310 | 4 | + 0.3 / 0.1 | 16 | + 0.6 / + 0.2 | I-310 |

| 3 | + 0.3 / 0.1 | 8 | + 0.4 / + 0.2 | I-310 | 4 | + 0.3 / 0.1 | 18 | + 0.6 / + 0.2 | I-310 |

| 3 | + 0.3 / 0.1 | 9 | + 0.4 / + 0.2 | I-310 | 4 | + 0.3 / 0.1 | 20 | + 0.6 / + 0.2 | I-310 |

| 3 | + 0.3 / 0.1 | 10 | + 0.4 / + 0.2 | I-310 | 4 | + 0.3 / 0.1 | 22 | + 0.6 / + 0.2 | I-310 |

| 3 | + 0.3 / 0.1 | 11 | + 0.4 / + 0.2 | I-310 | 4 | + 0.3 / 0.1 | 25 | + 0.6 / + 0.2 | I-310 |

| 3 | + 0.3 / 0.1 | 12 | + 0.4 / + 0.2 | I-310 | 4 | + 0.3 / 0.1 | 30 | + 0.6 / + 0.2 | I-310 |

| 3 | + 0.3 / 0.1 | 13 | + 0.4 / + 0.2 | I-310 | |||||

Izinzuzo

Izinzuzo zethu ze-tungsten Carbide strip strip:

1. Ukuqina okuphakeme kokushisa.

2. Anti-deformation ekushiseni okuphezulu.

3. Ukumelana okuhle okushisayo.

4. Ukusebenza okuphezulu okushisayo.

5. Ikhono elihle kakhulu lokulawula i-oxidation.

I-6. Ukulwa okunamandla kokushisa okuphezulu.

7. Ukuphikiswa okuhle kokugqwala kusuka kumakhemikhali.

8. Isici esigqoke kakhulu.

9. Isikhathi sokusetshenziswa isikhathi eside.

Isishuqulu

Iphakheji yemigoqo ye-carbide eyenziwe ngosimende:

Uma unemibuzo, wamukelekile ukuxhumana nathi nganoma yisiphi isikhathi!

Imishini yokukhiqiza

Ukugaya okumanzi

Spray eyomile

Gcinezela

I-TPA Press

Semi-Press

I-Hip enetho

Ukusebenza kwemishini

Okokumbaya

Ukusika ucingo

Ukugaya okuqondile

Ukugaya kwendawo yonke

Ukugaya kwendiza

Umshini we-CNC milling

Ithuluzi lokuhlola

Imitha ye-hardness

Umdlandla

Isilinganiso se-Quadratic element

Ithuluzi le-Cobalt Magnetic

I-MicrosCrographic DimcroScope