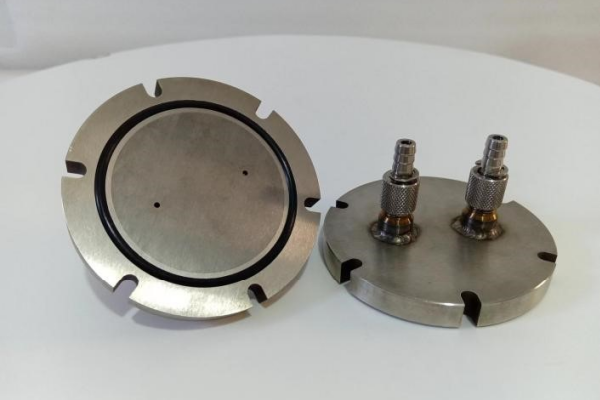

Tungsten carbide vacuum grang jar

Ukufanisa

I-Ball Mill Grinsing jar isetshenziswa ikakhulukazi ezindaweni zokucwaninga, izikhungo zokucwaninga namabhizinisi ukugaya amasampula okuhlola noma izinto zokukhiqiza ezivuthiwe, futhi ngesikhathi esinye imixube, ukusakaza futhi kube nemishini yokucubungula i-Ultra-Fine Pop-Fine. Ubukhulu bawo obusebenza kakhulu, obuncane, ukusebenza kahle kakhulu, ukusetshenziswa kwamandla okuphansi, ukusebenza okuqinile nokuzinzile, kungabonakala ezimbonini eziningi ezinjengamaminerali, amakhemikhali, izinto zokwakha, umuthi, i-elektroniki, njll.

I-Laborabula Rill yokugembula imvamisa inezimbiza ezi-4 zokugaya, ukunyakaza okusheshayo, izinto zokwakha zicutshungulwa ngokugaya, ukugaya okunamanzi, ukugaya okuphansi, njengamanje, njengamanje imishini yokucubungula i-Ultra-Fine ethandwa kakhulu.

Kungani Khetha Izinto Ze-Carbide zeTungsten ukwenza imbiza yokugaya?

Yize iplanethi yebhola lebhola linamandla futhi linekhono, i-tungsten carbide grain jar ebaluleke kakhulu. Inqubo yokugaya nokuxuba kwenziwa e-Carbide Ball Mill jar, ngoba imbiza yebhola le-carbide ball iyadingeka ukuba ne-seal enhle, ukugaya owomile nokumanzi kungenziwa. Imbiza ye-Carbide Graining yekhwalithi ephezulu kakhulu iyisinqumo esihle kunazo zonke.

Isicelo

I-Carbide Ball Mill Grinsing Ijar isetshenziswa ku-Planetary Ball Mill, ngebhola lokugaya le-Carbide, elisetshenziselwa ukugaya i-carbide powder, idayimane, idayimane kanye nobunye bunzima obuphezulu.

Ikusasa lembiza ye-tungsten carbide ukugaya imbiza

Ukumelana nokushisa okushisa okungu-1 .Ukushisa okusebenzayo kungafinyelela ku-1000 ° C.

2 .High ugqoke ukumelana ngo-500 ° C.

I-3 .High Hardness, Ubulukhuni be-Ultra-High buyizimpawu eziphambili ze-Carbide Carbide yokugaya izimbiza.

I-4 .strength kanye nobunzima, hhayi kuphela ubunzima obuphezulu, kodwa futhi kunobunzima obuhle kakhulu.

Ukucaciswa okujwayelekile

| Ivolumu (ml) | H (mm) | Od (mm) | I-id (mm) | Lip t (mm) | Udonga t (mm) |

| 50 | 61.5 | 48 | 36 | 8 | 6 |

| 100 | 59 | 63 | 51 | 6 | 6 |

| 25 | 69 | 86 | 74 | 10 | 6 |

| 500 | 96 | 105 | 92 | 14 | 6.5 |

| 1000 | 125 | 1350 | 115 | 14 | 7.5 |

Eminye imikhiqizo ongayithanda

Kunezinhlobo eziningana zezithombe ze-carbide zokugaya izimbiza njengaphansi:

Izinzuzo zethu

● Siyimboni enezinto ezingaphezu kweminyaka engu-15.

● I-OEM ne-ODM ayamukeleka.

● Amasampula azothunyelwa kungakapheli izinsuku ezi-3 zomsebenzi uma etholakala esitokweni.

● I-oda elincane lesilingo lamukelwa ngokubambisana kokuqala.

● Ubuchwepheshe bezinto ezibonakalayo zezingqinamba ezifunwayo

● Kusuka ku-Lab Ucwaningo ku-Batch Production

● Amakhono okucindezela ama-axial amaningi

● Zonke izikhunta zenziwe endlini

● I-HIP enethe

● Ukulethwa okusheshayo 4 ~ 6 amaviki

Imininingwane engaphezulu, wamukelekile ukuxhumana nathi nganoma yisiphi isikhathi!

Imishini yokukhiqiza

Ukugaya okumanzi

Spray eyomile

Gcinezela

I-TPA Press

Semi-Press

I-Hip enetho

Ukusebenza kwemishini

Okokumbaya

Ukusika ucingo

Ukugaya okuqondile

Ukugaya kwendawo yonke

Ukugaya kwendiza

Umshini we-CNC milling

Ithuluzi lokuhlola

Imitha ye-hardness

Umdlandla

Isilinganiso se-Quadratic element

Ithuluzi le-Cobalt Magnetic

I-MicrosCrographic DimcroScope